Didara simẹnti, irin shot pẹlu ga yiya resistance

Ṣafihan

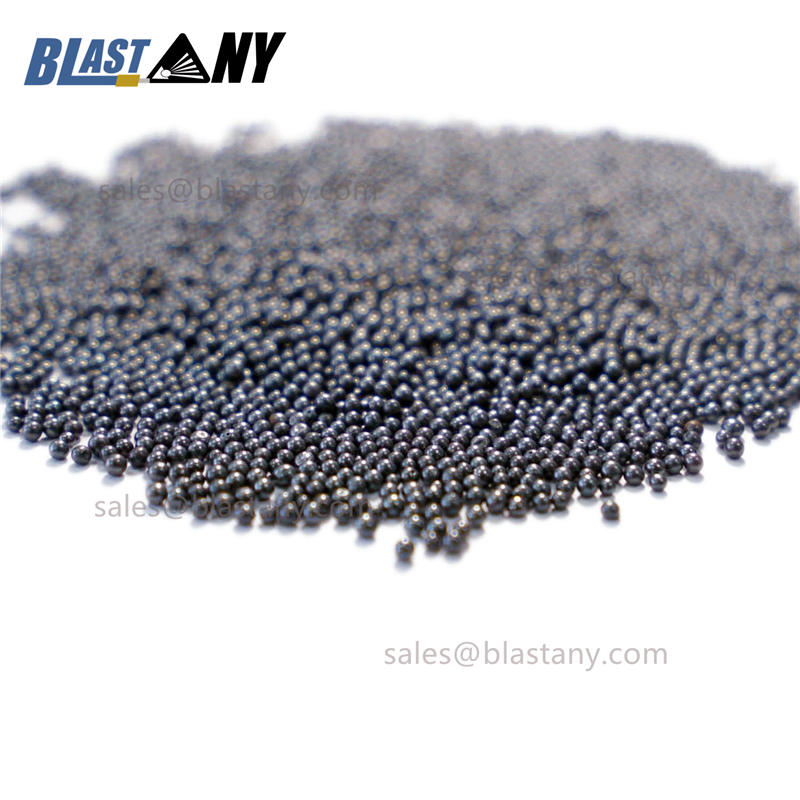

Junda Steel Shot jẹ iṣelọpọ nipasẹ yo alokuirin ti a yan ni ileru ifisi ina.Apapọ kemikali ti irin didà jẹ atupale ati iṣakoso ni muna nipasẹ spectrometer lati gba sipesifikesonu Standard SAE.Irin didà naa jẹ atomized ati yipada si patiku yika ati lẹhinna parun ati iwọn otutu ninu ilana itọju ooru lati gba ọja ti líle aṣọ ati microstructure, ti a ṣe ayẹwo nipasẹ iwọn ni ibamu si sipesifikesonu SAE Standard.

Junda ise, irin shot ti pin si mẹrin, a ti orile-ede boṣewa simẹnti irin shot, ti o ni awọn chromium simẹnti irin shot, ìşọmọbí fun kekere erogba, irin alagbara, irin, pẹlu ti orile-ede boṣewa simẹnti irin shot jẹ patapata ni ibamu pẹlu awọn orilẹ-ede boṣewa awọn ibeere ti akoonu ano ni gbóògì, ati awọn ano ti chromium simẹnti irin shot, ti wa ni da lori orilẹ-bošewa ti irin balls, fifi ferromanganese ferrochrome smelting ilana ni gbóògì eroja, gẹgẹ bi awọn Owen gbe to gun;Kekere erogba, irin shot gbóògì ilana ati orilẹ-pawọn irin shot, ṣugbọn awọn aise awọn ohun elo jẹ kekere erogba, irin, erogba akoonu ni kekere;Irin alagbara, irin shot jẹ iṣelọpọ nipasẹ ilana ilana atomizing, awọn ohun elo aise jẹ irin alagbara, irin, 304, 430 irin alagbara, irin ati bẹbẹ lọ.

Iru iru ibọn yii ni a ṣe fun lilo ninu fifun ibọn ati awọn ilana fifẹ labẹ titẹ nipasẹ afẹfẹ fisinuirindigbindigbin.O ti wa ni ipilẹ lo lori awọn irin ti kii ṣe irin gẹgẹbi aluminiomu, awọn alloy zinc, awọn irin alagbara, idẹ, idẹ, bàbà ...

Pẹlu titobi titobi rẹ ti awọn gradings, o ti lo fun mimọ, deburring, compaction, shot peening ati awọn ilana ipari gbogbogbo, lori gbogbo iru awọn ẹya, laisi ibajẹ oju rẹ nipasẹ awọn eruku ferrous eyiti o bajẹ ati yi awọ ti awọn irin ti a tọju pada.fun ilana ti ogbo ti okuta didan ati giranaiti.

Ohun elo ile-iṣẹ

Irin shot iredanu

Irin shot nu awọn simẹnti simẹnti ati sisun -on iyanrin ti awọn simẹnti lati ṣe awọn dada gba ti o dara cleanliness ati ki o beere roughness, ki o le jẹ anfani si awọn tetele processing ati bo.

Simẹnti irin shot fun Irin awo dada igbaradi

Simẹnti irin shot nu awọn ohun elo afẹfẹ ara, ipata ati awọn miiran aimọ nipa shot Blasting, ki o si lilo awọn igbale regede tabi awọn wẹ fisinuirindigbindigbin air lati nu soke awọn irin awọn ọja dada.

Irin Asokagba lo fun Engineering ẹrọ

Awọn Asokagba irin ti a lo fun mimọ ẹrọ le mu ipata kuro ni imunadoko, slag alurinmorin, ati awọ-ara ohun elo afẹfẹ, imukuro aapọn alurinmorin, ati mu agbara abuda ipilẹ pọ si laarin ibora yiyọ ipata ati irin, nitorinaa imudara didara derust ti apakan apoju ẹrọ ẹrọ.

Irin shot iwọn fun Irin alagbara, irin awo ninu

Lati le ṣaṣeyọri mimọ, itanna, itọju dada ijona nla ti awo irin alagbara, irin, o gbọdọ yan awọn ohun elo abrasive ti o yẹ lati yọ iwọnwọn kuro lati oju irin alagbara ti yiyi tutu.

Gẹgẹbi awọn onipò oriṣiriṣi, irin alagbara, irin dada nilo lati yan oriṣiriṣi abrasives iwọn ila opin ati ipin si ilana.Ti a ṣe afiwe si ilana kemikali ibile, o le dinku idiyele mimọ ati ṣaṣeyọri iṣelọpọ alawọ ewe.

Irin shot aruwo media fun Pipeline egboogi-ibajẹ

Awọn paipu irin nilo itọju dada lati le teramo resistance ipata.Nipa ibọn irin, awọn didan media, sọ di mimọ ati yọ ohun elo afẹfẹ kuro ati awọn asomọ ṣe aṣeyọri ipata ti a beere fun yiyọkuro ite ati ijinle ọkà, kii ṣe dada mimọ nikan ṣugbọn tun ni itẹlọrun ifaramọ laarin paipu irin ati ibora, ṣaṣeyọri ipa ipata to dara.

Irin shot peening okun

Awọn ẹya irin ti a ṣiṣẹ ni ipo ikojọpọ gigun kẹkẹ ati ti a tẹriba si iṣe ti aapọn gigun kẹkẹ nilo ilana fifin peening lati mu igbesi aye rirẹ dara si.

Simẹnti irin shot Awọn ibugbe ohun elo

irin Asokagba peening ti wa ni akọkọ lo ni okunkun processing ti awọn ẹya pataki bi helical orisun omi, bunkun orisun omi, igi alayidayida, jia, gbigbe awọn ẹya ara, ti nso, kamẹra ọpa, tẹ axle, asopọ opa ati be be lo.Nigbati ọkọ ofurufu ba balẹ, jia ibalẹ gbọdọ koju ipa nla ti o nilo itọju peening shot nigbagbogbo.Awọn iyẹ tun nilo itọju itusilẹ wahala igbakọọkan.

Imọ paramita

| Ise agbese | National Standards | Didara | |

| Iṣakopọ kemikali% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Lile | irin shot | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| iwuwo | irin shot | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Tempered Martensite tabi Troostite | Tempered Martensite Bainite Apapo agbari | |

| Ifarahan | Ti iyipo Awọn patikulu ṣofo <10% Pipati pa <15% | Ti iyipo Awọn patikulu ṣofo <5% Pipati pa <10% | |

| Iru | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Iṣakojọpọ | Toonu kọọkan ni Pallet lọtọ ati pupọnu kọọkan pin si awọn akopọ 25KG. | ||

| Iduroṣinṣin | 2500 ~ 2800 igba | ||

| iwuwo | 7.4g/cm3 | ||

| Iwọn opin | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Awọn ohun elo | 1. Fifọ aruwo: Ti a lo fun fifọ fifun ti simẹnti, ku-simẹnti, ayederu;yiyọ iyanrin ti simẹnti, irin awo, H iru irin, irin be. 2. Ipata yiyọ: Ipata yiyọ ti simẹnti, forging, irin awo, H iru irin, irin be. 3. Shot peening: Shot peening ti jia, ooru mu awọn ẹya ara. 4. Shot iredanu: Shot iredanu ti irin profaili, ọkọ ọkọ, irin ọkọ, irin ohun elo, irin be. 5. Itọju-iṣaaju: Itọju-itọju ti dada, irin ọkọ, irin profaili, irin ọna, ṣaaju ki o to kikun tabi ti a bo. | ||

Iwon Distribution Of Irin Shot

| SAE J444 Standard Irin shot | Iboju No. | In | Iwọn iboju | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| GBOGBO kọja | 6 | 0.132 | 3.35 | |||||||||||

| Gbogbo Pass | 7 | 0.111 | 2.8 | |||||||||||

| 90% iṣẹju | Gbogbo Pass | 8 | 0.0937 | 2.36 | ||||||||||

| 97% iṣẹju | 85% iṣẹju | Gbogbo Pass | Gbogbo Pass | 10 | 0.0787 | 2 | ||||||||

| 97% iṣẹju | 85% iṣẹju | 5% ti o pọju | Gbogbo Pass | 12 | 0.0661 | 1.7 | ||||||||

| 97% iṣẹju | 85% iṣẹju | 5% ti o pọju | Gbogbo Pass | 14 | 0.0555 | 1.4 | ||||||||

| 97% iṣẹju | 85% iṣẹju | 5% ti o pọju | Gbogbo Pass | 16 | 0.0469 | 1.18 | ||||||||

| 96% iṣẹju | 85% iṣẹju | 5% ti o pọju | Gbogbo Pass | 18 | 0.0394 | 1 | ||||||||

| 96% iṣẹju | 85% iṣẹju | 10% ti o pọju | Gbogbo Pass | 20 | 0.0331 | 0.85 | ||||||||

| 96% iṣẹju | 85% iṣẹju | 10% ti o pọju | 25 | 0.028 | 0.71 | |||||||||

| 96% iṣẹju | 85% iṣẹju | Gbogbo Pass | 30 | 0.023 | 0.6 | |||||||||

| 97% iṣẹju | 10% ti o pọju | 35 | 0.0197 | 0.5 | ||||||||||

| 85% iṣẹju | Gbogbo Pass | 40 | 0.0165 | 0.425 | ||||||||||

| 97% iṣẹju | 10% ti o pọju | 45 | 0.0138 | 0.355 | ||||||||||

| 85% iṣẹju | 50 | 0.0117 | 0.3 | |||||||||||

| 90% iṣẹju | 85% iṣẹju | 80 | 0.007 | 0.18 | ||||||||||

| 90% iṣẹju | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Awọn Igbesẹ iṣelọpọ

Ogidi nkan

Ṣiṣẹda

Gbigbe

Ṣiṣayẹwo

Aṣayan

Ìbínú

Ṣiṣayẹwo

Package

Awọn ẹka ọja